Iron-based amorphous strip

Thanks to the following characteristics, iron-based amorphous alloys offer the advantage of low iron loss: ⋅ Thin thickness—only about 1/10 that of grain-oriented silicon steel; ⋅ High resistivity—about twice that of grain-oriented silicon steel; ⋅ Low coercivity—only about 1/3 that of grain-oriented silicon steel.

Categories:

Strip material

Key words:

Next

Next

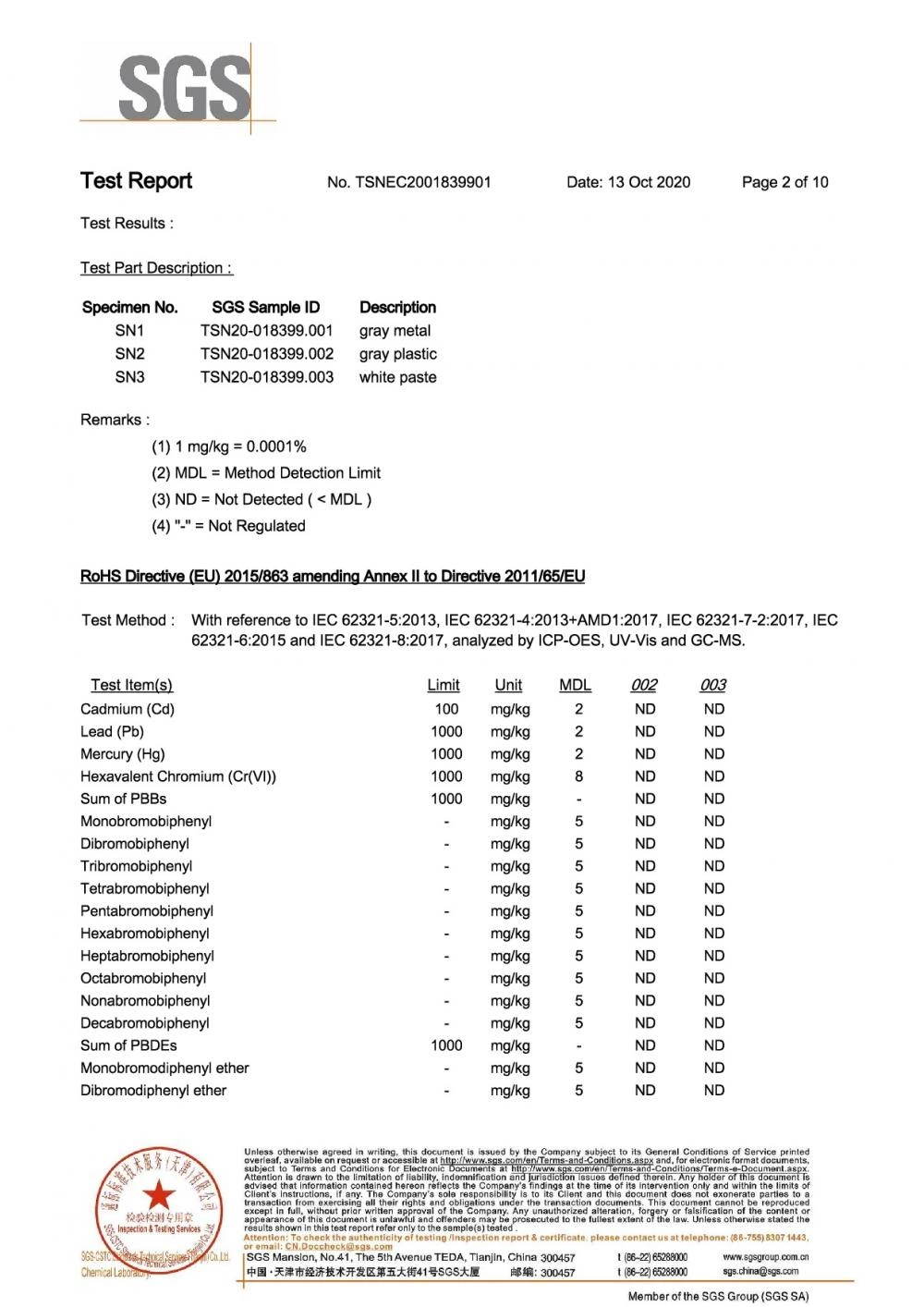

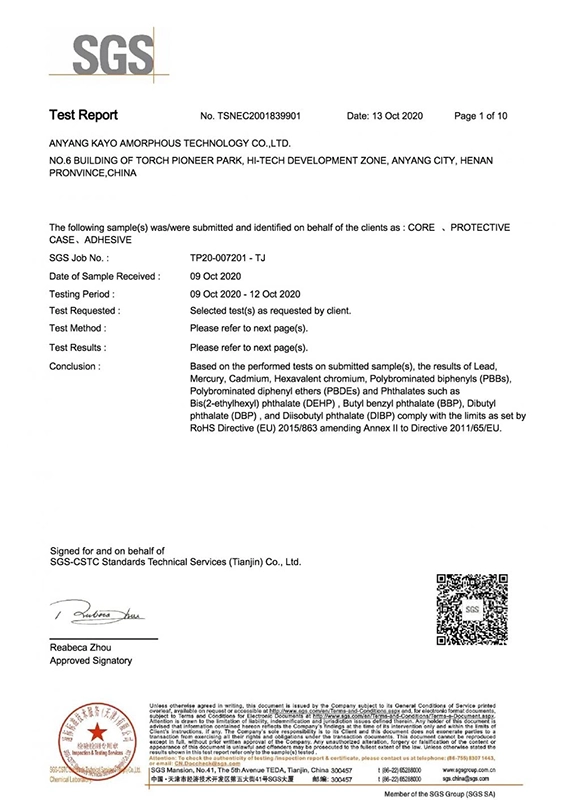

Certification

Providing better soft magnetic materials and solutions for customers has been our long-term goal.

Certification

Certification

Certification

Certification

Certification

Get A Quote

Leave your contact information and get a free product quote

Related Products

Providing better soft magnetic materials and solutions for customers has been our long-term goal.

Cobalt-based amorphous nanocrystalline alloy strip

Thanks to their unique microstructure, cobalt-based amorphous alloys boast core advantages such as ultra-low losses and ultra-high permeability: • Near-zero magnetostriction—resulting in noise-free operation and distortion-free signals; • Ultra-high permeability—far superior to conventional iron-based amorphous alloys and silicon steel; • Extremely low coercivity—offering sensitive response and lower energy losses. Cobalt-based amorphous alloys exhibit stable performance across a wide temperature range and at high frequencies, with strong anti-interference capabilities, making them ideal for precision sensing and high-frequency applications. We can tailor products to meet specific customer needs, offering customized solutions with features such as low noise, high sensitivity, and low losses at high frequencies.

Amorphous Nanocrystalline Strip

Amorphous strip material is a new type of functional material characterized by a unique atomic structure and outstanding comprehensive performance. It primarily consists of elements such as iron, silicon, and boron. This material exhibits excellent properties including low coercivity, high magnetic permeability, high resistivity, resistance to high-temperature corrosion, and high toughness.

Iron-based nanocrystalline strip material

• It boasts high permeability, high saturation magnetic induction, low coercivity, and low losses—its overall performance significantly outperforms conventional iron-based amorphous alloys, silicon steel, and certain permalloy alloys. • It exhibits strong frequency adaptability, with low losses and high efficiency at medium and high frequencies, making it suitable for a wide range of applications. • Its cost is substantially lower than that of cobalt-based amorphous alloys, offering outstanding value for money. • It demonstrates excellent temperature stability and reliable, consistent performance, making it ideal for large-scale industrial applications.

Thanks to the following characteristics, iron-based amorphous alloys offer the advantage of low iron loss: ⋅ Thin thickness—only about 1/10 that of grain-oriented silicon steel; ⋅ High resistivity—about twice that of grain-oriented silicon steel; ⋅ Low coercivity—only about 1/3 that of grain-oriented silicon steel.