Cobalt-based amorphous nanocrystalline alloy strip

Thanks to their unique microstructure, cobalt-based amorphous alloys boast core advantages such as ultra-low losses and ultra-high permeability: • Near-zero magnetostriction—resulting in noise-free operation and distortion-free signals; • Ultra-high permeability—far superior to conventional iron-based amorphous alloys and silicon steel; • Extremely low coercivity—offering sensitive response and lower energy losses. Cobalt-based amorphous alloys exhibit stable performance across a wide temperature range and at high frequencies, with strong anti-interference capabilities, making them ideal for precision sensing and high-frequency applications. We can tailor products to meet specific customer needs, offering customized solutions with features such as low noise, high sensitivity, and low losses at high frequencies.

Amorphous Nanocrystalline Strip

Amorphous strip material is a new type of functional material characterized by a unique atomic structure and outstanding comprehensive performance. It primarily consists of elements such as iron, silicon, and boron. This material exhibits excellent properties including low coercivity, high magnetic permeability, high resistivity, resistance to high-temperature corrosion, and high toughness.

Iron-based nanocrystalline strip material

• It boasts high permeability, high saturation magnetic induction, low coercivity, and low losses—its overall performance significantly outperforms conventional iron-based amorphous alloys, silicon steel, and certain permalloy alloys. • It exhibits strong frequency adaptability, with low losses and high efficiency at medium and high frequencies, making it suitable for a wide range of applications. • Its cost is substantially lower than that of cobalt-based amorphous alloys, offering outstanding value for money. • It demonstrates excellent temperature stability and reliable, consistent performance, making it ideal for large-scale industrial applications.

Thanks to the following characteristics, iron-based amorphous alloys offer the advantage of low iron loss: ⋅ Thin thickness—only about 1/10 that of grain-oriented silicon steel; ⋅ High resistivity—about twice that of grain-oriented silicon steel; ⋅ Low coercivity—only about 1/3 that of grain-oriented silicon steel.

The iron-based amorphous filter inductor core boasts excellent frequency characteristics, superior performance under AC-DC superposition, and extremely low iron losses. At the same time, its permeability can be flexibly adjusted over a very wide range (from 120 to 1200 microhenries), enabling it to effectively handle varying levels of bias current ampere-turns and localized magnetic fields. This product is suitable for inductor applications in a variety of high-frequency and AC-DC superposition scenarios, and its performance outperforms that of silicon-iron-nickel and iron-aluminum magnetic powder cores.

The newly designed leakage-current protection core replaces permalloy with materials that feature high magnetic permeability, low coercivity, and low losses. It is highly sensitive to even the slightest leakage currents while also demonstrating excellent resistance to high-current surges. Additionally, it boasts outstanding thermal stability and can operate reliably in ambient temperatures ranging from -25°C to 100°C. Consequently, this new type of magnetic ring can be widely used in leakage-current protective switches.

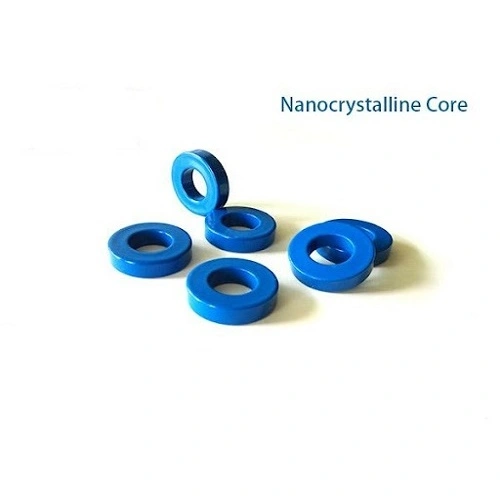

Amorphous/Nanocrystalline Core (for Residual Current Devices)

The newly designed leakage current protection magnetic core replaces traditional materials with a Permalloy alloy that boasts high magnetic permeability, low coercivity, and low losses. Our high-performance magnetic core is exceptionally sensitive to even the slightest leakage currents, while also demonstrating outstanding resistance to high-current surges and remarkable thermal stability, enabling reliable operation in ambient temperatures ranging from -25°C to 100°C. Consequently, this superior magnetic ring is ideally suited for use in leakage current protective switches.

Amorphous Nanocrystalline Common-Mode Choke Core

CMC magnetic cores feature high saturation magnetic flux density, enabling effective reduction in the size of CMC devices. At the same time, they exhibit excellent resistance to unbalanced currents as well as superior impedance and temperature stability. Consequently, they are widely used in inverter circuits, variable-frequency drive cores, uninterruptible power supplies (UPS), switch-mode power supplies, EMC filters, and new energy applications.

Insulated ferrite core, toroidal soft magnetic core

Ferrite soft magnetic materials are materials that can be easily magnetized and demagnetized under weak magnetic fields. They mainly include zinc-copper ferrites and nickel-zinc ferrites. These materials have a wide range of applications, come in numerous varieties, are produced in enormous quantities, and boast high economic value. They are primarily used to manufacture various inductive components, such as filter cores, transformer cores, radio-frequency cores, and magnetic heads for audio and video recording. At the same time, they are also crucial materials for magnetic recording devices.

High-precision inductors, miniature current transformers, power transformers, and instruments and meters.

Silicon steel core for transformers

Materials · We use high-quality CRGO steel with low iron loss and high magnetic permeability, available in thicknesses of 0.1 mm, 0.23 mm, 0.27 mm, 0.3 mm, and 0.35 mm. Features - It features a ring-shaped structure, with the winding direction aligned with the closed magnetic circuit, eliminating magnetic leakage. As a result, it exhibits the finest magnetic performance. Moreover, the ring-type winding machine is used for coil winding, making the process simple and highly efficient. Applications · Ring cores are widely used in magnetic components found in 50 Hz and 400 Hz transformers, current transformers, chokes, and other electronic devices.

Amorphous Nanocrystalline Power Transformer Core

High-quality power transformer magnetic ring ● High saturation magnetic flux density, which can effectively reduce the size and weight of the device. ● High permeability and low coercivity, which enhance efficiency and reduce copper losses. ● Low loss, which helps lower the transformer’s temperature. ● Stable temperature performance, enabling continuous operation from -45℃ to 130℃.